Product Overview of Cracking tube

Cracking furnace tube is the core component of cracking furnace. According to the furnace tube arrangement can be divided into horizontal tube type and vertical tube type.

In order to increase the cracking depth to obtain the highest ethylene yield as possible, most ethylene plants have widely used 25Cr35Ni series alloy steel to replace the original 25Cr35Ni series alloy steel, and its heat resistance temperature has been increased from 1050 ~ 1080 ℃ to 1100 ~ 1150 ℃. Considering that the cracking temperature and residence time are limited by the heat resistance of the radiation furnace tube, combined with the existing conditions of the production plant, it is decided to use the alloy material 35Cr45NiNb with higher Cr and Ni. The mass fraction of chromium is 34.0% ~ 37.0%, and the mass fraction of nickel is 43.0% ~ 48.0%. The material has good high temperature oxidation resistance under the condition of ensuring high thermal strength.

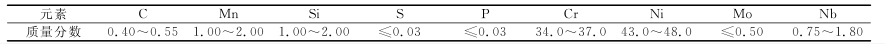

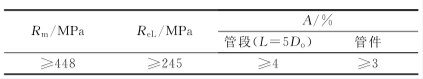

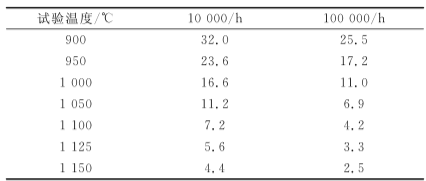

The chemical composition of the furnace tube and pipe fittings (35Cr45NiNb alloy steel) should meet the requirements of Table 1, and its mechanical properties at room temperature should meet the requirements of Table 2. The high temperature sustained breaking time of the material should meet the requirements of the sustained breaking time under the test conditions specified in the standard. The average stress value at 10000h and 100000h fracture shall not be less than the requirements in Table 3.

Table 1 Chemical composition of 35Cr45NiNb alloy steel (mass fraction %)

Table 2 Mechanical properties of 35Cr45NiNb alloy steel at room temperature

Table 3 The average fracture stress of 35Cr45NiNb alloy steel at high temperature MPa

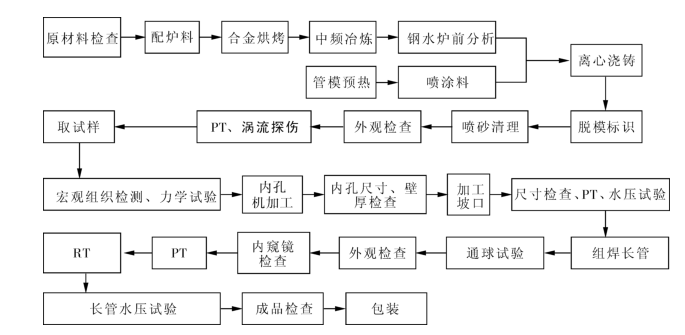

Centrifugally cast furnace tubes are generally used for cracking furnace tubes. The process flow of furnace tubes from tube section casting, mechanical processing, assembly and welding to inspection and delivery is as follows:

Where to buy Cracking tube?

If you have any questions about Cracking tube, please don't hesitate to contact us at any time. We will provide detailed information and technical support about the features, specifications, solutions and customization options. Welcome you to visit our factory!