Good noodles rely on rolling, good steel relies on rolling. The steel billets produced from the steelmaking plant are only semi-finished products and must be repeatedly rolled by the rolling mill to become qualified products. As an important process of hot rolling, heating is not something that an ordinary furnace can handle. It requires this steel monster that has risen from the ground in 93 days~~

Rolling is a pressure processing process that changes the shape of steel ingots and billets between rotating rollers. On the one hand, it obtains the desired shape, and on the other hand, it also improves the internal quality of the steel.

Our common automotive panels, bridge steel, boiler steel, pipeline steel, threaded steel, steel bars, electrical silicon steel, galvanized steel, tinplate, including train wheels... They are all processed through the steel rolling process.

↓↓ Threaded steel ↓↓

↓↓ Pipeline steel ↓↓

↓↓ Train wheel ↓↓

Heating metal materials or workpieces at high temperatures before rolling can improve their plasticity and reduce deformation resistance. Simultaneously improving the internal structure and properties of the metal, homogenizing the uneven structure in the billet through diffusion, and eliminating segregation... The quality of heating temperature control directly affects the quality of rolled steel products.

The heating equipment used for this job cannot be an induction cooker or a boiler, but a specialized industrial furnace: a heating furnace. To distinguish it from the process of heating steel into molten steel before becoming an ingot, it is sometimes referred to as a reheating furnace. It is divided into two categories: chamber type heating furnace and continuous heating furnace (including pusher type, walking type, rotary bottom type, and chamber type). The walking beam continuous heating furnace can move the billet forward step by step through a series of actions such as raising, advancing, lowering, and retreating of the furnace bottom (walking beam furnace) or water-cooled metal beam (walking beam furnace).

Due to the large-scale rolling mill, the walking beam heating furnace is more and more widely used because of its advantages such as flexible material transportation, high output per unit furnace bottom area, good heating quality, less land occupation and energy saving.

BENDOTTI, an Italian company founded in 1916, built a 120t/h slab walking beam heating furnace for the steel plant of NLMK GROUP, a major Russian steel manufacturer, in VERONA, Italy, with a construction period of 93 days. This steel factory mainly produces steel ingots and thick steel plates, with two-thirds of its production sold in Italy and the rest sold to various continents.

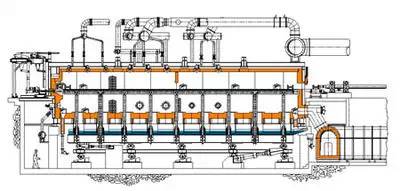

↓↓ Structural diagram of 125t/h walking beam heating furnace ↓↓

↓↓ Day 92, almost completed ↓↓

↓↓ Day 5. This is basically a big hole here

↓↓ Day 19. to pave nicely

↓↓ Day 29. Start stacking up

↓↓ Day 52. It's not enough to stack, it's higher on the edge

↓↓ Day 54. Continue stacking

↓↓ Day 65. You can refer to this step for the next buffet stack salad

↓↓ Day 77. A heating furnace generally consists of seven parts: the heating furnace body, cooling system, combustion system, inlet and outlet materials, smoke exhaust system, waste heat recovery system, and automatic control system.

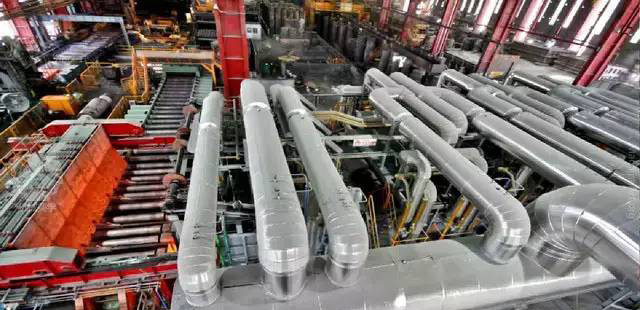

↓↓ Day 79. The walking beam is usually composed of water-cooled pipes, and the walking heating furnace can achieve double-sided heating of the billet up and down.

↓↓ Day 81. Pay attention to the second thick tube on the left

↓↓ Day 82. Each pipe should be wrapped in insulation material

↓↓ Day 86. Ten thousand foot steel pipe lifted from the ground

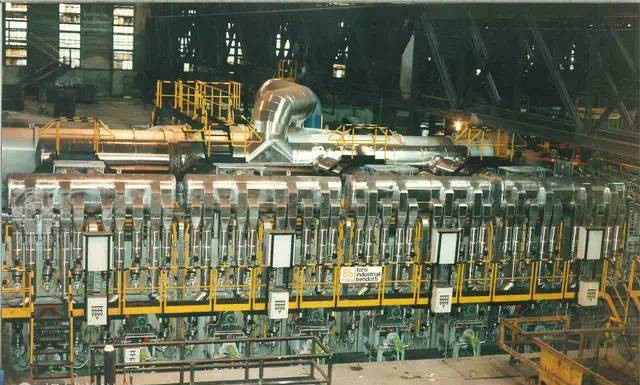

↓↓ DEACERO -120t/h walking beam heating furnace discharge machine

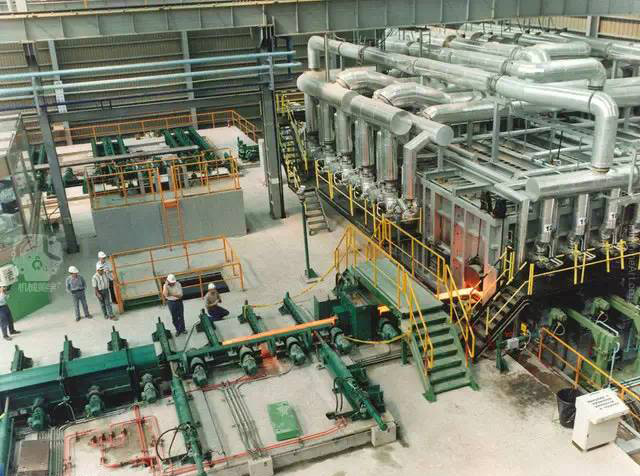

↓↓ The walking beam heating furnace built in 2007

↓↓ The walking beam heating furnace built in 1992

↓↓ The walking beam heating furnace built in 1995

↓↓ Walking bottom heating furnace

↓↓ OFFICINE TECNOSIDER-60 t/h pusher type heating furnace. In the early days, pusher type furnaces were more commonly used, but beam type furnaces were more flexible in transporting materials, and if necessary, all furnace materials could be discharged from the furnace; The billet is placed at intervals on the bottom or beam of the furnace, allowing for rapid and uniform heating; Completely eliminating the arch steel and sticking steel faults of the pusher type furnace, thus ensuring that the length of the furnace is not limited by these factors.

↓↓ The burning red iron block swished past my feet, making it a warm underfloor in winter and an oven in summer

↓↓ The newly produced steel is warm. 90 t/h Hermetik L.S. walking beam furnace, with a total size of 7X18 meters, natural gas fuel, flame cleaning capacity of 235.000 tons/year, processing size of 160x160 mm to 240x240 mm, and speed of 30 meters/minute